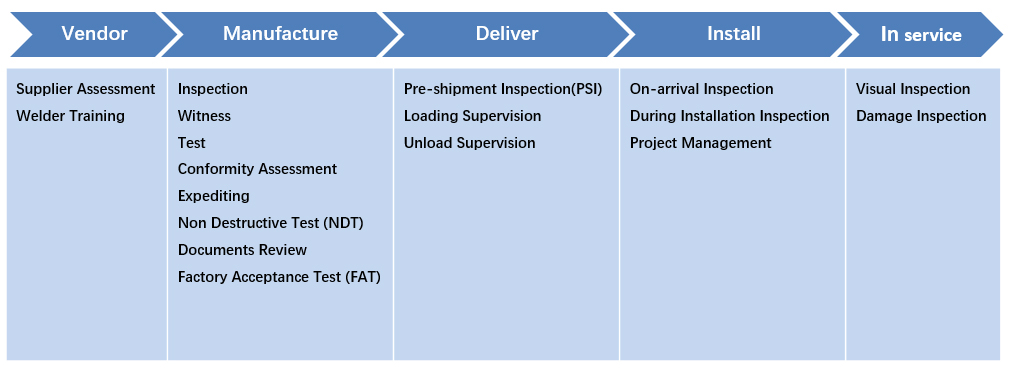

In industry field, CCIC Canada is CSA W178.1 certified inspection organization (company code: CCICC8). The inspection scope covers pipeline, oil and liquids facilities, contract terminal, steel building, metal construction, industrial equipment.Besides production inspection service, CCIC Canada provides inservice verification, product conformity assessment, project management, welder training and management system consultation, etc. Our excellent CWB(Canadian Welding Bureau) certified inspectors and experienced ISO/CSA/AWS/CWI/DIN/ASME/ASTM/NDE engineers, as well as other professional engineer in the field are ready to perform one-stop-service from manufacturing to installation.

Procurement

• Supplier Recommendation

Economic globalization has made international procurement a norm. Customers of CCIC Global Industrial Inspection services are your preferred supplier resources. With in-depth knowledge of customer quality, we help you build the most competitive global supply chain.

• Supplier Evaluation

Global procurement complicates supplier evaluation. Uncertain international emergencies and travel restrictions add to the difficulty of business. CCIC Global Industrial Inspection services help your quality expectations and compliance requirements be met in the global supply chain.

Our services include but are not limited to:

• Effectiveness of supplier’s management system of quality, safety, environmental protection, social responsibility and other guarantee systems.

• Verification of supplier’s R&D capabilities, production capabilities, and contract performance capabilities.

• Product compliance

• Contract compliance

…

• Management Consultation

The standard and certification regulations of various countries pose challenges to global supply. CCIC Global Industrial Inspection service engineers are familiar with the certification requirements of various countries. They are expertised at integrating overseas regulations with the existing management system of suppliers, and achieve system integration with the lowest cost and in the way that customers like. To achieve the purpose of system upgrade.

Our services include but are not limited to:

• CSA660-Certification of Manufacturer’s of Steel Building Systems

• CSA47.1-Certification of companies for Fusion Welding of Steel

• CSA59-Welded Steel Construction

• Welding inspection and quality assurance document setup and review: ITP; NCR, CAR, PAR, Delivery package

…

• Training for Qualification

Many certification require suppliers to have an operating team that meets the recognized qualifications, which requires suppliers to accurately master the standards, quickly train and smoothly obtain relevant qualifications. CCIC Global Industrial Inspection can customize training courses for suppliers according to your project requirements, benchmark certification regulations and standards, assist in obtaining certification qualifications, and quickly train an operation team that meets your project requirements.

Our services include but are not limited to:

• W47.1 Workshop for Supervisors and Inspectors

• W59 Workshop for Supervisors and Inspectors

• Welding Supervisor – Steel

• Welding Supervisor – Aluminum

• Welding Inspector Level 1

• Welding Inspector Level 2

…

Manufacture

• Inspection

Any defects in the manufacturing process may result in high cost of use. With the rich practical experience and professional inspection, CCIC Global Industrial Inspection services team will not let go of any visible and potential defects, helping you avoid additional costs and eliminate quality risks in the manufacturing stage.

Our services include but are not limited to:

• Welding inspection

• Anticorrosion inspection

• Structural inspection

• …

• Witness

Critical control points determine product quality and project success or failure. CCIC Global Industrial Inspection experts identify these critical points for you, and appear on the spot at appropriate times to witness, transmit and save witness information, provide independent witness analysis conclusions and expert recommendations. .When equipment or components fail and lead to litigation, our witness experts can provide objective evidence and witness statements to effectively protect your legitimate rights and interests.

• Test

Obtain data through testing to prove that the product meets regulations, specifications and quality standards. CCIC Global Industrial Inspection service provides world-leading mechanical testing services to global customers to determine the characteristics and defects of materials used in products or projects to ensure that components and equipment can operate reliably and match your requirements.

Our services include but are not limited to:

• Mechanical performance test

• Function test

• Positive Material Identification(PMI)

• Material performance testing

• Air tightness test

• Pressure detection…

• Expediting

The competition of industrial projects is the competition of supply chain efficiency. The expediting service of CCIC Global Industrial Inspection service allows you to win at the starting line, because we do not only supervise, but also guide and assist, by reviewing the supplier’s production plan and capacity allocation to help optimize and improve and ensure that your project is completed with the best efficiency.

• Non Destructive Test (NDT)

Non-destructive testing can be used to detect defects, chemistry, and physical parameters of materials, parts, and equipment using principles such as radiation, ultrasound, infrared, and electromagnetic technology without disassemble and downtime. The professional non-destructive testing program of CCIC Global Industrial Inspection service is going to minimize the impact of inspection on the manufacturing schedule.

Our services include but are not limited to:

• Radiographic Testing (RT)

• Ultrasonic Testing (UT)

• Phased Array Ultrasonic Testing (PAUT)

• Magnetic Particle Testing (MT)

• Eddy Current Testing (ET)

• Guided Wave Testing (GWT)

…

• Technical Documents Review

In order to meet your procurement requirements, the quality of the technical documents prepared by the suppliers, such as processes, standards, procedures, and methods, often fundamentally determines the quality and efficiency of supply. CCIC Global Industrial Inspection service experts have extensive industry experience to provide complete integration services to ensure the technical documents are compliant and applicable.

Our services include but are not limited to:

• Welding procedure assessment

…

• Factory Acceptance Test (FAT)

The factory acceptance test is the last quality barrier before the product is completed and delivered. CCIC Global Industrial Inspection is here to check for you. We verify whether the product is in compliance, whether it meets the design standards and all quality requirements, and whether the function meets your needs and expectations.

Our services include but are not limited to:

• Compliance inspection

• Integrity check

• Contract compliance verification

• Function detection

• Final confirmation of equipment and components

…

Deliver

• Pre-shipment Inspection (PSI)

In order to ensure the shipment and safe-arrival of qualified products, CCIC Global Industrial Inspection provides you with independent and professional pre-shipment inspection services, including quality, quantity, marking, and packaging, to ensure compliance with quality standards, technical specifications and contract requirements.

Our services include but are not limited to:

• Visual inspection

• Witness test

• Document review

• Packaging and marking inspection

• Load check

• Transportation inspection

• …

• Supervision of Loading and Unloading

In order to minimize the impact of handling, loading and unloading on the quality of product delivery, CCIC Global Industrial Inspection provides you with supervised loading and unloading services to ensure that your goods move safely and properly around the world and provide independent proof of the status of the goods.

Our services include but are not limited to:

• Packaging and quantity inspection

• Monitor loading, unloading and handling

• Check the packaging location

• Check handling tools

• Check transportation tools

• Check fixing and protective measures

…

Install

• Inspection during installation

The installation is the last mile before the industrial equipment is put into production. How to identify and control the risks in this process, let the installation process coordinate and promote safety, CCIC Global Industrial Inspection comprehensively considers equipment, regulations, environment, construction period, budget and other factors for you to provide integrated solutions.

Our services include but are not limited to:

• Installation drawing review

• Installation process evaluation

• Receiving inspection

• Confirmation of critical control points

• No-load debugging inspection

• Load commissioning inspection

• Output inspection

…

• In-service Inspection

The continuous safe operation of industrial equipment and ensuring the continuous qualified output of products are the expectations of each operator. CCIC Global Industrial Inspection provides regular in-service inspection services for your equipment to ensure the safe operation of your equipment and avoid the possibility of failure and downtime. Reduce system risks and economic losses, and let your equipment reach its maximum potential and benefits.

• Damage inspection

When a component or equipment fails, CCIC Global Industrial Inspection helps you quickly identify the cause of the failure, define responsibilities, assess losses, and through professional inspection, testing, and failure analysis, formulate preventive measures to prevent recurrence, while providing effective solutions and scheme to put your equipment/facility back into use.